Developed & designed by metrologists for metrologists & calibration technicians

Transform your resistance standards calibration with Measurements International’s (MI) latest innovation – the Automated Resistance Standard model 1310A. This user-friendly, cost-effective solution provides military organizations, national and third-party labs with unparalleled accuracy and confidence in their resistance standards.

Designed with input from a world-renowned National Measurement Institute, the model 1310A delivers exceptional results, making it the go-to choice for organizations looking to take their calibration to the next level. Upgrade your calibration process today and trust in the precision and reliability of MI’s Automated Resistance Standard

| Feature | Benefit |

| 9 resistors 1 Ω, 10 Ω, 100 Ω, 1 kΩ, 10 kΩ, 100 kΩ, 1 MΩ, 10 MΩ, 100 MΩ, 1 external channel. | Complete line of decade value standards in one temperature-controlled enclosure. |

| Hand-picked high precision resistors in temperature-controlled chamber. |

Delivers highest level of performance from the internal high precision resistors. |

| Internal resistance elements in a temperature-controlled chamber. | Excellent stability and extremely low-temperature coefficients. |

| Single output cable for direct plug-in. | Easy operation without requirement for changing wires. |

| Built for calibration of calibrators and DVMs. | Best stability < 2.5 μΩ/Ω/Year. |

| Built-in 4-terminal scanner. | Combining two instruments into one simple to use instrument. |

| External extra channel. | Connect to resistance value of your choice. |

| Front panel or GPIB controlled. | Simplifies operation for user. |

| Internally mounted temperature sensor PT100. | Users can connect to front panel and monitor internal oven. |

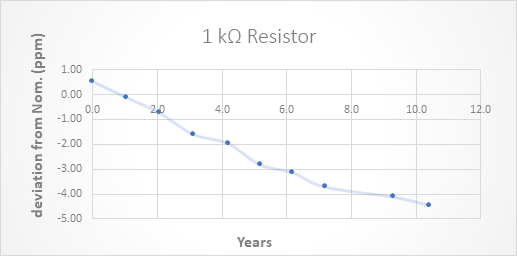

Figure 1. Drift of MI Resistor Over a 10 Year Period

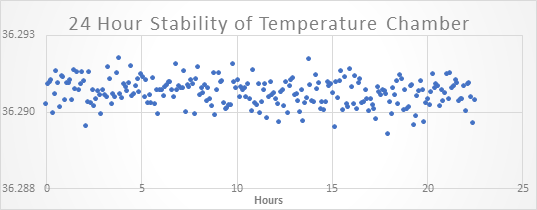

Figure 2. 24-Hour Stability Testing Internal

Temperature Chamber

| Nominal Resistance (Ohms) |

Nominal Resistance (± μΩ/Ω) (± ppm) |

24 Hour Stability (± μΩ/Ω) (± ppm) |

12 Month Stability (± μΩ/Ω) (± ppm) |

Temperature Coefficient (± μΩ/Ω/°C) (± ppm/°C) |

Max. Voltage (Volts) |

|---|---|---|---|---|---|

| 100 MΩ | 50 | 0.4 | 10 | 0.025 | 100 |

| 10 MΩ | 35 | 0.25 | 10 | 0.025 | 100 |

| 1 MΩ | 25 | 0.03 | 2.5 | 0.02 | 100 |

| 100 kΩ | 15 | 0.02 | 2.5 | 0.01 | 100 |

| 10 kΩ | 10 | 0.01 | 2.5 | 0.005 | 32 |

| 1 kΩ | 10 | 0.01 | 2.5 | 0.005 | 10 |

| 100 Ω | 10 | 0.01 | 2.5 | 0.005 | 3.2 |

| 10 Ω | 10 | 0.01 | 2.5 | 0.005 | 1.0 |

| 1 Ω | 10 | 0.01 | 2.5 | 0.005 | 0.32 |

| Temperature Stability | ± 0.1 °C Over a 1 Year Period | ||||

| Ambient Temperature Range | 23 °C ± 5 °C | ||||

| Ambient Humidity Range | 20 to 70 % RH | ||||

| Warranty | Standard 2 Year Parts & Labour | ||||

Scanner Specifications

| Operation | Four-Terminal |

| Error Contribution | < 20 Nanovolts |

| Contact Configuration | Relay – Two Coil Latching |

| Max Carrying/Switching Current | 4/2 Amps @ < 30 Volt (DC) |

| Maximum Working/Switching Voltage | 1000/220 Volts @ < 100 mA (DC) |

| Contact Resistance | < 0.05 Ω |

| Expected Relay Life | 108 Operations |

| Insulation Resistance | > 1012 Ω |