We are proud to introduce you to the new 6800C Quantum Hall Standard System developed by Measurements International (MI) – the ultimate solution for highly accurate and traceable reference standards in hi-tech environments. The Quantized Hall Resistance (QHR) Standard is globally recognized as the representation of the ohm and is the most stable resistance standard. With the MI 6800C QHR System, national laboratories and primary industrial laboratories worldwide can now have access to a fully automated primary standard that is not only highly reproducible but also an economical means of providing a highly reliable resistance standard.

Gone are the days of struggling with liquid helium shortages, erratic deliveries, and increasing prices. The 6800C QHR System requires no liquid helium to operate, making it an efficient and cost-effective solution for laboratories. The MI team has invested many years of experience in quantized Hall system design, resistance measurements, and cryogenics to develop the 6800C QHR System, a modular system consisting of three parts: sample, cryogenics system, and bridge measurement system. These components can be purchased separately, providing the flexibility to customize the system to meet individual laboratory requirements.

Moreover, we offer several options to enhance the system’s functionality, including extra QHR samples and 6800C software. With MI’s new 6800C QHR Standard System, laboratories can now meet their measurement goals efficiently and accurately without compromising on quality, reliability, or cost.

Sample

The QHE device is mounted on a special probe that passes through an airlock so as to maintain the system clean and free of atmospheric gas and other impurities that may otherwise condense. This is especially important when using unprotected QHE devices as they need to be protected from water contamination. Two probes are offered, one as described for metrology purposes and the second for general use as a research tool.

The system has been specially designed for a dual sample platform to allow for GaAs/AlGaAs and Graphene QHR sample use. Both samples can be inserted at the same time for sample to sample comparison.

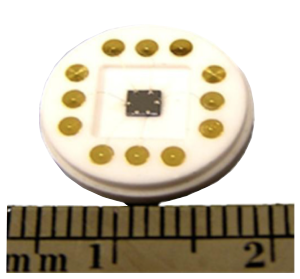

The standard sample platform has 8 electrical connections using PTFE insulated silver wiring to a TO-8 socket. The probe is shipped with two TO-8 sample platforms as standard. A copper cover protects the sample during insertion and removal.

The 6800C Resistance Standard sample provides the absolute value of resistance related to the von Klitzing constant of 25 812.807 4593 Ω. Operating on step I = 2 plateau and i = 4 plateau, the 6800C compares the QHR value of 12906.40373 Ω to either a 10 kΩ or 1 kΩ resistor. The reference or sample developed at the National Research Council of Canada (NRCC) for Gallium Samples, and developed at the National Standards Institute of Technology (NIST) for Graphene-based samples.

The 6800C system also supports other manufacturers’ samples.

The 6800C offers customers ultra-reliable and high-performance range of Cryogen-Free Magnet Systems with sample space temperatures ranging from 1.3 K to 300 K and magnetic fields up to 9 Tesla in our standard system – all without the need for liquid cryogens. Special system designs are available to also offer customers a temperature range of 0.3 K to 300 K and magnet systems up to 14 Tesla.

The use of patented technology allows the whole system to be operated from a pulse-tube cryocooler. Reliable, precise and highly stable temperature control is achieved during normal measurement sequences.

Once connected to mains power, these systems can be turned on and operational within several hours. With service intervals ≥ 30,000 hours, the system may be used continuously over very long periods, or simply as needed, providing complete freedom to plan research work and optimize running costs.

The modular and configurable system architecture allows a variety of different sample probes to be used within a compact size single vertical field cryo-magnet to perform a wide range of measurements.

The integrated VTI is cooled by the cryocooler and self generates a small volume of liquid 4He from an external gas reservoir. The 4He gas is cooled by a series heat exchanger which terminates in a Joule-Thompson valve. Here the gas expands, cooling and so condensing to provide the low-temperature environment. An external mechanical vacuum pump is used to reduce the temperature to 1.3 K.

Samples are top loaded into the sample access column via an airlock and gate valve located at the top of the sample space to allow access to the centre of the magnet temperature controlled region. There is no need to bring the sample space to room temperature for sample exchange. Experienced operators can typically change samples in a few minutes.

The 6800C provides the precision-controlled environment in which all sample measurements are performed. Temperature control with stability at the mK level is achieved using a continuous flow of recirculating 4He gas in the closed-loop. This proven and reliable technology wastes no 4He gas in normal operation and ensures precisely controlled stable sample temperatures in the range from below 1.3 K to 100 K.

The 1 W cryocooler provides sufficient cooling to ensure the temperature remains stable and homogeneous within 100 mK over a height of at least 5 cm from the bottom of the VTI, where the samples will be placed, even while sweeping the magnetic induction at 0.5 T/min rate.

| Sample Space | 30 mm / 40 mm | ||

| Temperature Range (with Continuous Gas Flow in VTI) |

Below 1.3 K to 100 K with 40 cubic metre scroll pump |

||

| Temperature Control | 5 mK @ 10 K 10 mK @ 100 K |

||

| Typical Sample Cool-Down Time to 1.3 K | 10 minutes with VTI cold | ||

| Temperature Stabilization Time for a Typical 5 K Temperature Step and 0.1 K Accuracy |

|

Optional 3He: Helium-3 Ultra-Low Temperature Insert

The Cryogenic range of Helium-3 inserts is designed to extend the range of experimental temperatures. Using only the cooling power of the VTI and two internal temperature-controlled sorption pumps, the sample platform of the Helium-3 insert can be maintained at any temperature from below 300 mK to above 10 K.

The insert fits inside the 6800C variable temperature space and the 3He pot has a working volume of liquid 3He of approximately 1.5 cc. The standard insert features a gold-plated copper sample mounting surface. For QHR, use a TO-8 socket is anchored to the 3He pot with suitable low thermal voltage wiring to the socket from room temperature.

The QHR sample is mounted directly on the 3He probe in an inner vacuum chamber. Because the sample is outside the 3He reservoir it can be changed without risk of losing the 3He charge. The sample is well-grounded thermally and all the wiring to the sample is fully thermally grounded while maintaining the very high level of electrical insulation required for QHR work.

A thermometer and a heater is fitted to the 3He insert to allow its temperature to be measured

and controlled.

| Base Temperature | < 300 mK |

| Working Temperature Range | < 300 mK – 100 K |

| Outer Diameter | 22 mm (to suit 30 mm VTI) |

| 3He Capacity | Total 3He gas volume 1.5 STP litres Working volume in normal use approx 1.0 STP litres |

| Initial Cooldown Time | 2 hours from room temperature sample change to 3He condensation temperature under standard cryogen-free VTI operating conditions |

| Recondensation Time | 25 minutes to condense 90 % of 3He charge and cool pot to below 2 K |

Cryocooler Specifications

| Cryocooler | |

| Cooling Powers at 50 Hz | 1st Stage: 35 W @ 45 K, 2nd Stage: 0.9 W @ 4.2 K |

| Base Temperature | < 3 K |

| Orientation | Vertical Only |

| Maintenance Interval | 30,000 hrs – 40,000 hrs |

| Ambient Temperature | 5 °C to 35 °C |

| Compressor – F70LP/H (Water Cooled) | |

| Main Power Requirement | 7.2 kW (steady), 8.5 kW (max), 3-phase F70LP: 200 V @ 50 Hz & 60 Hz F70H: 380 – 415 V @ 50 Hz – 480 V @ 60 Hz |

| Water Cooling | 6.8 – 9 L/min |

| Ambient Temperature | 5 °C to 35 °C |

| Charcoal Absorber Life | 30,000 hrs |

| Flexible Gas Lines | 20 A × 20 m |

| Compressor Dimensions | W – 444 mm, L – 529 mm, H – 576 mm |

| Weight | 100 kg |

Cooling Water

The Pulse Tube Cryocooler requires a continuous flow of cooling water. We recommend the use of a recirculating water chiller to provide a reliable source of cooling water for the compressor of the cryocooler. Chillers can be purchased as part of the complete system.

Magnet

The 6800C cryostat includes one of our liquid helium free superconducting magnets producing a vertical magnetic field with the central bore of 52 mm. The homogeneity of the magnet is 0.02 % over a volume of 1 cm³. The magnet is designed to operate with a 120 A 5 V power supply.

Maximum Magnetic field Range 9 Tesla Tesla

Central field homogeneity 0.02 % over 1 cm³ at the field centre

Persistent mode decay rate of 10 ppm/hr

Ramp Rates 15 minutes to 9 Tesla

The 6800C measurement system includes the AccuBridge® 6020Q ADCC bridge operating in room temperature air, enabling two resistors to be compared with accuracies to better < 0.02 ppm.

Since 1994, the 6010 technology has set the standard for DC Current Comparator (ADCC) Resistance Bridge performance in calibration laboratories globally. The time has now come to advance this best-in-class series, taking advantage of twenty-first century AccuBridge® ADCC technology.

Measurements International’s (MI) major technological advantage in resistance measurements is the development of the only commercially available portable Quantum Hall System, 6800C, which uses an AccuBridge® ADCC technology bridge as the measurement system operated in ambient temperatures. Like all our ADCC bridges the current range is from 1 µA to 200 mA for use as a Quantum Hall Bridge and a resistance bridge. The ADCC 6020Q features increased ampere turn sensitivity (more turns) on both the slave and master windings and a new voltage feedback circuit to improve on the linearity error of the nanovolt amplifier.

MIL has world-class expertise in both DC Resistance Metrology at NMI’s and 17025 Accreditation throughout the industry. As your accreditation partner and global support partner, MIL offers leading product knowledge and applications expertise through coaching, system design, implementation, calibration services and ongoing expert support ensuring your competitive advantage.

It’s not only about the equipment or the science…it’s about what that will enable you to do, and the ease with which you can do it.

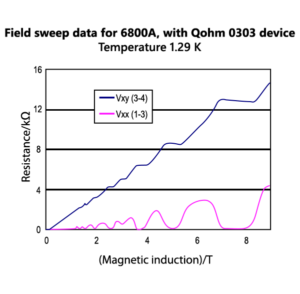

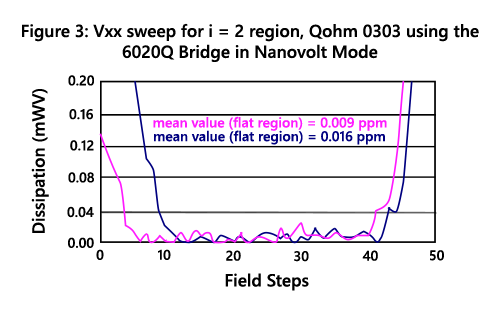

The AccuBridge® 6020Q room temperature ADCC Quantum Hall Resistance Bridge can be used to characterize both the GaAs/AlGaAs or Graphene samples by measuring and plotting the field sweep, the contact resistance (Vcr), the longitudinal resistance and dissipation of the I = 2 plateau (Vxx) and transferring the Hall Resistance (Vxy) to a 1,000 Ω standard resistor.

Enhancements using AccuBridge® ADCC technology include a higher ampere-turn sensitivity covering a wider range of resistance ratio, a current and voltage feedback circuit for increased linearity performance and a new calibration technique with increased resolution in obtaining even tighter specifications. In addition to the updated technology, it carries the 6010’s dependability, simplified calibration, ease of use, automation, speed of measurement and worldwide support making the 6020Q the best and only Resistance Bridge that offers uncertainty specifications that rival anything available today.

The AccuBridge® 6020Q is a fully automated bridge. Its speed, precision and measurement accuracy accounts for its preferred status as the primary resistance bridge in most NMIs throughout the world. It is designed for flexibility and ease of use and is perfectly suited for stand-alone resistor calibrations.

The AccuBridge® 6020Q has two inputs, Rx and Rs. The number of inputs can be expanded to 40 when used in conjunction with the 4200 Series Low-Thermal Four Terminal Matrix Scanners. Measurements can be performed automatically and with Measurements International’s 6020Q software delayed or scheduled measurements can all be performed at any time. Automatic current reversal ensures that DC offsets and thermals in the bridge and scanner are cancelled out during the measurement. See the 4200 Data Sheet for a complete range of Matrix Scanners.

As a stand-alone device, the 6020Q is capable of performing the sweep check, contact resistance, the longitudinal potential difference (dissipation) and hall resistance measurements on the QHR sample. Menu-driven functions are selectable using the front panel display or over the GPIB-488. In addition, the 6020Q DCC current comparator bridge can be used as a high accuracy DC resistance ratio bridge in its own right for calibrating resistors using either a 1 Ω or 10 KΩ standard resistor. For laboratories that don’t have a QHR system, the 6020Q can be used to build up from the 1 Ω or down from the 10 kΩ.

Sweep Check Measurement: The 6020Q performs the field sweep check measurement by feeding the current into the Source & Drain of the sample and then reversing it. This allows the measurement of potential differences between various points on the sample. These potential differences can be measured at Hall resistances Vxy (1-2) or Vxy (3-4) and the longitudinal resistance Vxx (1-3) and Vxx (2-4) on the sample. Vxy (1-2) and Vxy (3-4) should be in close agreement with each other as should Vxx (1-3) and Vxx (2-4).

Contact Resistance Measurements are made using the microvolt detector in the 6020Q. It is important to measure the contact resistance each time the QHR device is cycled to room temperature and re-cooled as large contact resistances can lead to errors in the QHR measurement. The 6020Q uses a three probe measurement on each of the contacts in turn to measure the contact resistance. The contact resistance is equal to Vcr/I = resistance of wire + resistance of contact + resistance of 2-Deg. The contact resistance should be ideally less than 1 Ω.

Dissipation: For an accurate transfer of the QHR value it is also necessary to measure the longitudinal potential difference. This can be accomplished by measuring between Vxx (1-3), and Vxx (2-4) using the 6020Q Vxx nanovolt mode. This measurement is taken to verify that there is no dissipation in the 2-Deg. When the 2-Deg is quantized Vxx should go to 0 and should be < 2 × 10-8 of Vxy.

For traceable measurements, the QHR value and related uncertainty are entered in the resistor ID standards file and the 1,000 Ω transfer resistor into the measurand (unknown) ID file from the keypad. Standard Resistors such as the 1 Ω or 10 kΩ are entered into the standards file after they have been calibrated. Resistors to be calibrated are entered into the measurand (Rx) or unknown file. Measurement functions such as current through the unknown resistor, settle time, a number of measurements and number of statistics are also entered into the Programs file using the keypad on the touch screen.

Full System Integration, Testing & Installation

All systems are fully tested in our works prior to delivery and the customer is welcome to visit at this time to observe the tests and receive training in its operation. The installation will be carried out by our engineers at the customers’ site, at which time further training is given to the users.

We include an installation with time allowed for the training of the system based on up to 3 days.

The system can operate with 50 or 60 Hz 3-phase high or low voltage. (See Cryocooler Specifications)